Project management

• Conception, design and execution from a single source

• Filling studies / distortion analyses (mould-flow analyses) / long-term tests

• Tool making and cooperation with local toolmakers

• Sample / prototype tools

• Inspection on special fixtures or using a 3D measurement machine

• Sampling / EMPB-manufacturing (PPAP) / IMDS-entry

• Change management

• IT- supported information exchange (e.g. EDI)

• Mass production

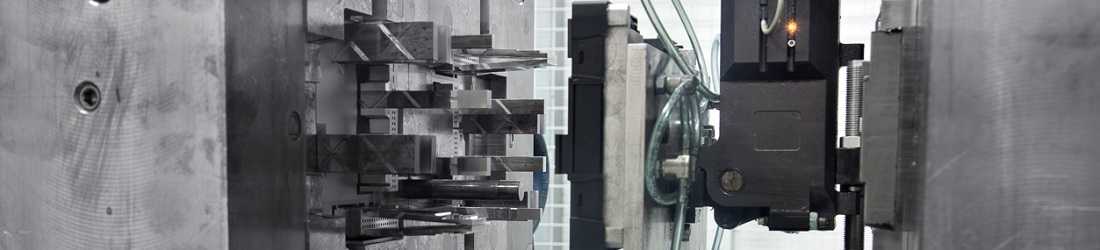

Tool making

For many years we have now been working together with several toolmaking partners in Baden-Württemberg area.

Quick and flexible changes or modifications to tools are a matter of course for us, just as the maintenance and care of tools is.

Production

We manufacture plastic parts to the highest technical demands and sophisticated designs on 17 state-of-the-art computer-controlled injection molding machines networked via the Arburg host computer system (ALS) and freely programmable handling and automation systems. Besides the advanced injection moulding technology we have also specialised on the mounting and multi-component technology.

Logistics

We supply our customers worldwide and ensure a fast and low cost transport to the final destination. Structured processes and workflows ensure a high delivery reliability and flexibility with fast reaction times. Together we define comprehensive need-based logistic concepts, take care of product optimised packaging and high performance containers. Above and beyond this we have a well-stocked material and finished parts warehouse and are in a position to react quickly to short-term changes in demand.

• Just-in-Time / Just-in-Sequence

• Kanban

• SupplyOn Plattform

• MAT-Labels

• Packaging and transport concept (small load containers / ESD)

• Willing to operate credit procedure (consignment stock)

• Shipping / customs