Technology in detail

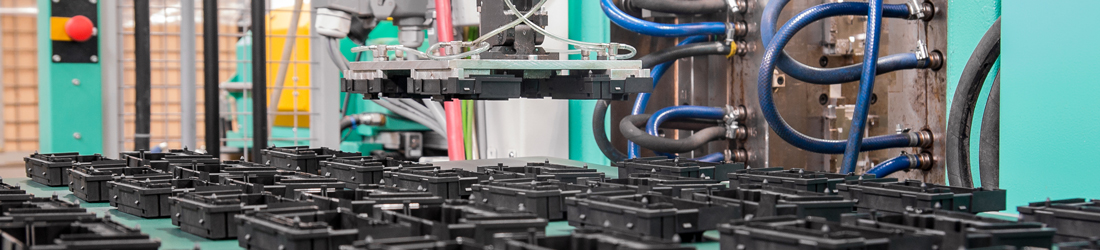

We are equipped with 2C-injection moulding machines from Arburg with the latest technology and computer supported machine control and process monitoring.

Currently we manufacture on machines with as closing force range of 25 to 220 tons. As a result we can manufacture finished parts with a moulded weight of 0.5 g to 400 g. Besides the demanding injection moulding technology we have also specialised on the manufacture of subassemblies and multiple component injection moulding. In addition complex plastic housings and the overmoulding of metal components (e.g. brass bushes, contacts, pins or circuit boards) are also part of our core competencies.

Vertical and horizontal injection moulding and injection moulding at separate levels also belong to our capabilities.

Materials used

Since we also process highly temperature resistance materials the safety precautions and instructions, which are very important to us, must be complied with.

Here is a small extract of the plastics used:

• Polycarbonate (PC)

• Polypropylene (PP)

• Polyamide (PA6 / PA6.6) - reinforced: 0-50% GF

• Polybutylene Terephthalate (PBT) - reinforced: 0-50% GF

• Polymethylmethacrylate (PMMA)

• Polyoxymethylene (POM)

• Acrylonitrile butadiene styrene (ABS)

• Liquid Crystal Polymer (LCP)

• Thermoplastic Elastomers (TPE)

• Liquid Silicone Rubber (LSR)